IMPEDER

SMACO IMPEDER CASING

Epoxy-Glass Casing

Made from epoxy reinforced fiberglass material. It is least expensive with high wear resistance; recommended for flow through impeder

Ferro-Glass Casing

Made from ferrite powder filled with epoxy / fibre glass material, is recommended for exposed ferrite impeder.

Sil-Glass Casing

Made from silicon resin bonded fiberglass material, able to withstand high temperature but lower wear resistance. Recommended for impeder with support on both ends.

SMACO IMPEDER ASSEMBLY

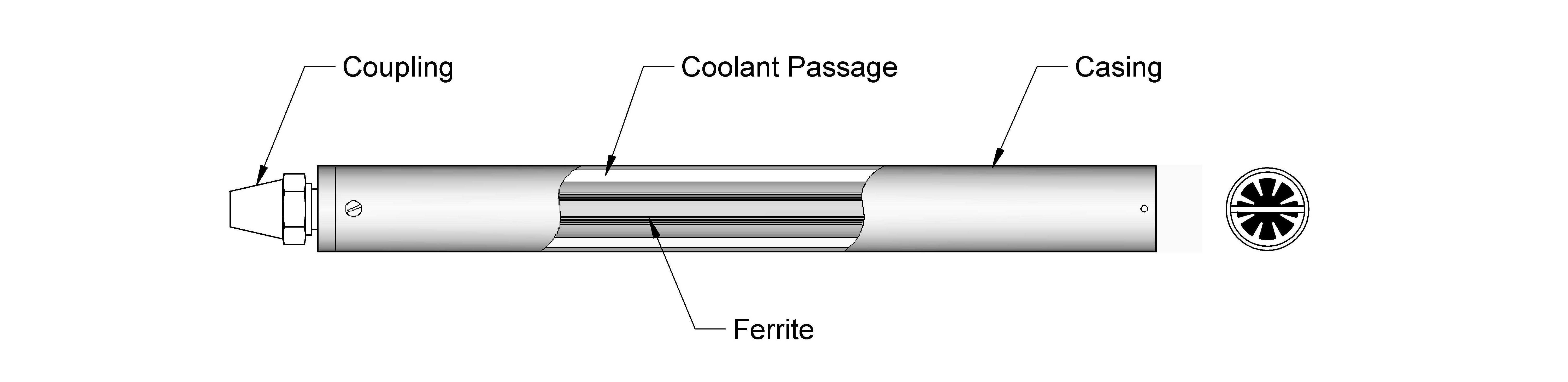

FLOW THROUGH IMPEDER

Most commonly used impeder assembly with coolant directly flowing through. Contain one or more ferrite core insider the casing; one end fitted with brass coupling and other end with pin or collar with pin.

Slotted ferrite is recommended; with larger surface area for efficient cooling needed for performance. (Available with 3 different casing material and length 230, 330, 430, 630 & 830 mm).

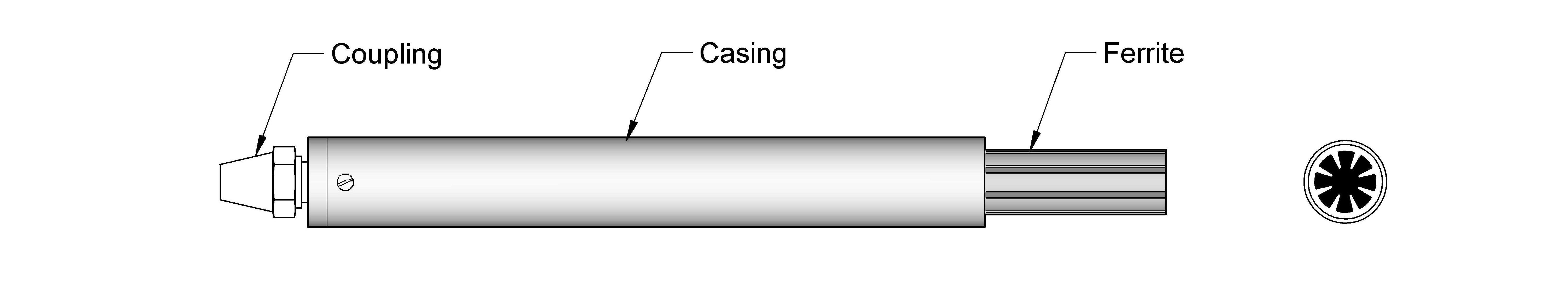

EXPOSED FERRITE IMPEDER

Ideal for welding small tube with limited space for impeder and coated (galvanized/aluminized) material. Being exposed at the end, the design allowed "larger ferrite than normal" to be used.

This enable higher weld speed per kW and narrow heat affected zone. The exposed end also allows coolant to wash away hot metal or zinc deposited on the impeder placed below weld centerline, therefore giving a longer impeder life span

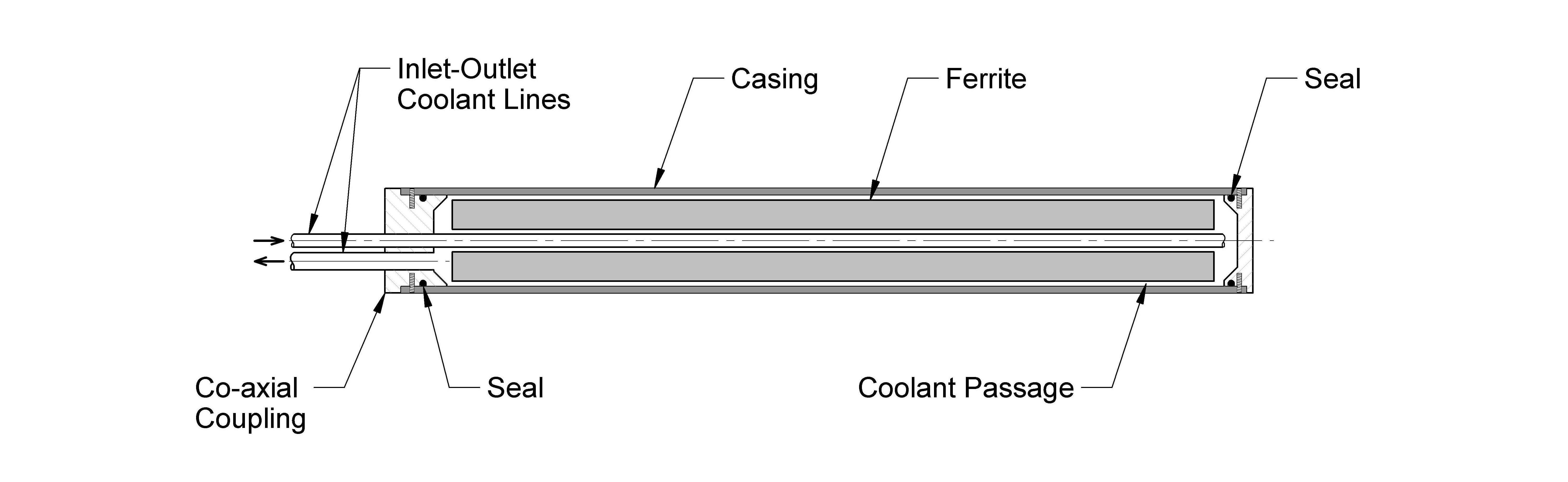

RETURN FLOW IMPEDER

Used when it is necessary to keep the inside of welded tube dry and clean. Typical applications are inline galvanizing and internal painting. Contain one or more ferrite core inside the casing; one end is fitted with coaxial coupling for coolant entry and exit, and another end plugged with special bonding agent for better leak proof.

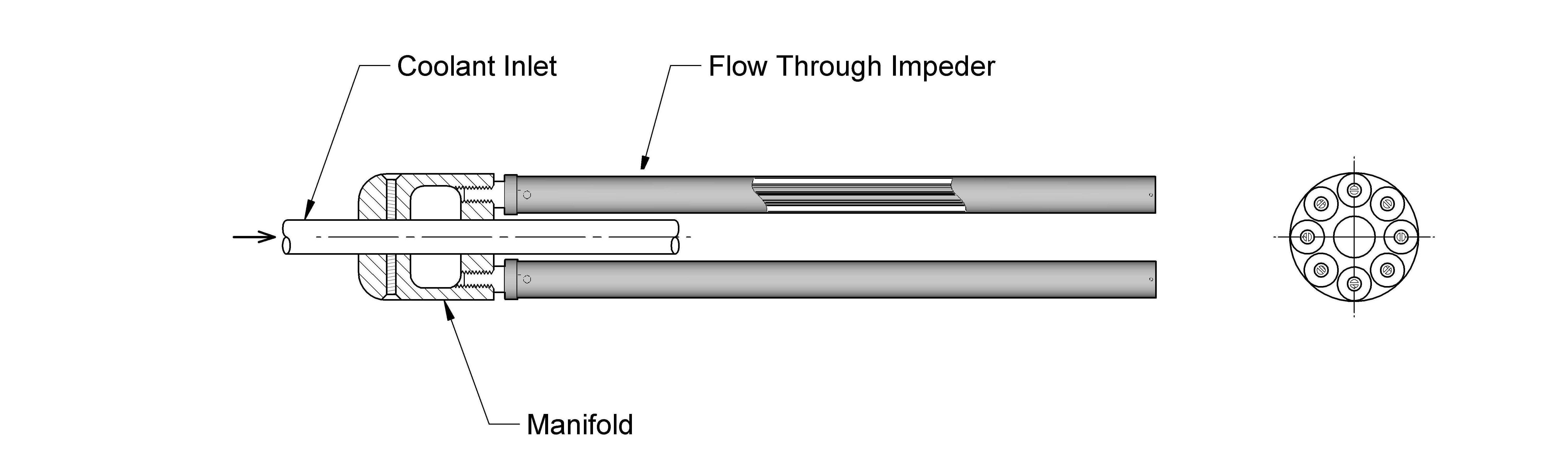

CLUSTER IMPEDER

Recommended for welding large pipe, normally above 2.5" diameter. It is an economical alternative to expensive oversize single piece of ferrite. This is an assembly of standard flow through impeder mounted to a manifold support by mandrel. The design allows standard flow through impeder types to be used for different tube size. The result is low stock of ferrite material, and replacement is mainly for ferrite close to weld area.